Industry Knowledge Development

The AC CBB65 capacitor is a type of motor run capacitor commonly used in air conditioning (AC) systems. It provides the necessary electrical energy to start and run the AC motor efficiently.

The term "explosion-proof" in relation to capacitors typically refers to their ability to withstand internal failures or faults without causing an explosion or a safety hazard. Explosion-proof capacitors are designed with safety features to minimize the risks associated with failure, such as short circuits or internal faults.

These safety features often include self-healing properties, where any small electrical faults or breakdowns within the capacitor are automatically repaired by the capacitor itself. This prevents the fault from escalating and causing catastrophic failure.

When choosing an

AC CBB65 explosion-proof capacitor, there are several factors you should consider to ensure the capacitor meets your requirements and is suitable for your application. Here's a step-by-step guide to help you make the right choice:

1.Determine the required capacitance: The capacitance value you need will depend on your specific application and the electrical requirements of the system. Check the specifications or consult with an expert to determine the appropriate capacitance rating for your AC circuit.

2.Voltage rating: AC capacitors have voltage ratings that indicate the maximum voltage they can handle. Make sure the explosion-proof capacitor you choose has a voltage rating equal to or higher than the voltage in your AC circuit. It's generally recommended to have a capacitor with a higher voltage rating than the maximum voltage in the system to provide a safety margin.

3.Current rating: Consider the current rating of the capacitor, which refers to the maximum current the capacitor can handle. Ensure that the chosen capacitor can handle the current demands of your AC circuit without exceeding its rated capacity. Oversizing the current rating is generally a good practice to ensure longevity and safety.

4.Size and dimensions: Take into account the physical dimensions of the capacitor to ensure it fits within the available space in your system. Check the dimensions of the capacitor, including its length, width, and height, to ensure it can be easily accommodated.

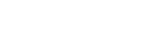

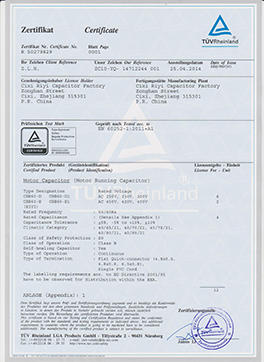

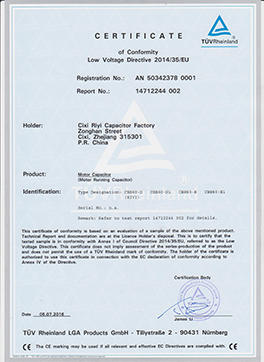

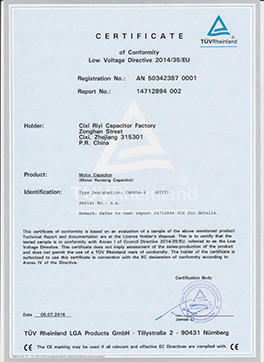

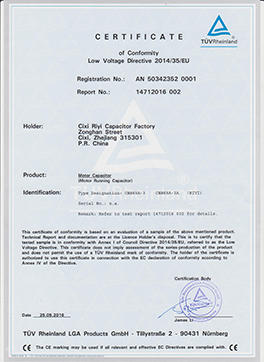

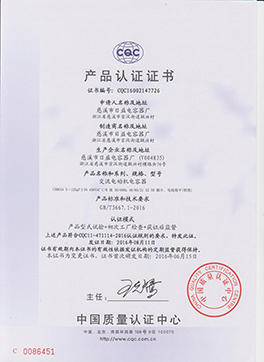

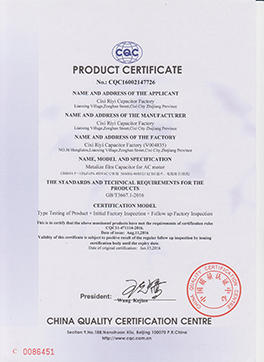

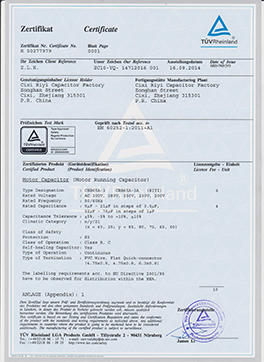

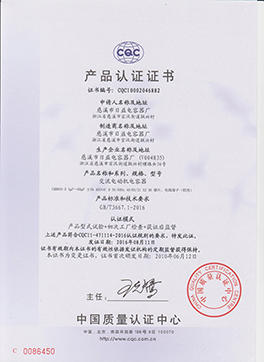

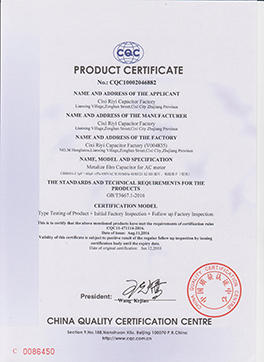

5.Safety certifications: Look for explosion-proof capacitors that have appropriate safety certifications from reputable organizations or regulatory bodies. These certifications ensure that the capacitor has been tested and meets certain safety standards. Examples of certifications include UL (Underwriters Laboratories), CSA (Canadian Standards Association), and CE (Conformité Européene).

6.Durability and construction: Consider the construction quality and durability of the capacitor. Look for capacitors with robust and reliable construction that can withstand the operating conditions of your system. Additionally, consider factors such as resistance to high temperatures, humidity, and vibration if they are relevant to your application.

7.Supplier reliability: Choose a reputable and reliable supplier or manufacturer for your explosion-proof capacitor. Research and read reviews to ensure they have a good track record of delivering high-quality products.

8.Price considerations: While price should not be the sole determining factor, it's important to consider your budget and compare prices from different suppliers. Remember that cheaper options may not always guarantee the same level of quality and reliability.

简体中文

简体中文 English

English Español

Español عربى

عربى

+86-13600614158

+86-13600614158

+86-0574-63223385

+86-0574-63223385 Zonghan Street,Cixi City,Zhejiang Province,China.

Zonghan Street,Cixi City,Zhejiang Province,China.